EE1-0.002 Leverage Table dial gauge

Characteristic

Model : EE1-0.002

PDF-0.002 Leverage Table dial gaugeThe indicator - the proper use of a dial indicator method

1, the table is fixed to the table or table seat frame, stable and reliable. When the instruction sheet clamping, the clamping force can not be too large, so as not to deform the sleeve stuck spindle.

2, adjust the table spindle axis is perpendicular to the test plane of the cylindrical workpiece spindle axis to be perpendicular to the axis of the workpiece, or will cause large errors and damage indicator.

3, prior to the measurement zero position. Absolute measurement using a plate made zero reference, comparing the measured zero to do with comparative reference material (Block).

When the zero position, the first probe to make contact with the plane, so that the pressure probe pointer rotation is greater than the large circle, turn the dial so that 0 line and large pointer alignment, then lift the end of a pole and then let go of it falling 1-2mm , repeated 2-3 times to check if the pointer remains aligned with the 0 line, such as missing the retune.

4, measurement, gently lift the rod, the workpiece probe into the measured, can not be forcibly pushed under the workpiece probe. Significant irregularities without instruction sheet workpiece measurement.

5. Do not hit the measuring rod suddenly fell on the workpiece can not be strong vibration, beat indicator.

6, pay attention when measuring the measurement range of the table, not to the displacement of the probe out of range, so as to avoid excessive elongation of the spring, damage indicator.

7, not to probe too much to do with the spindle motion invalid, otherwise it will accelerate the wear and tear of parts, so that the table lose their accuracy.

8, when the spindle movement occurs arrest can not force pushing the probe should be sent to the metering chamber treatment.

Leverage Table dial gauge

EE1- 0.002 Leverage Table dial gauge

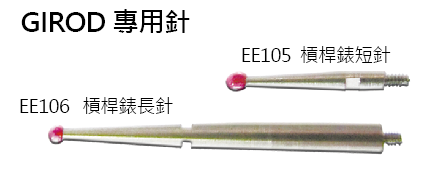

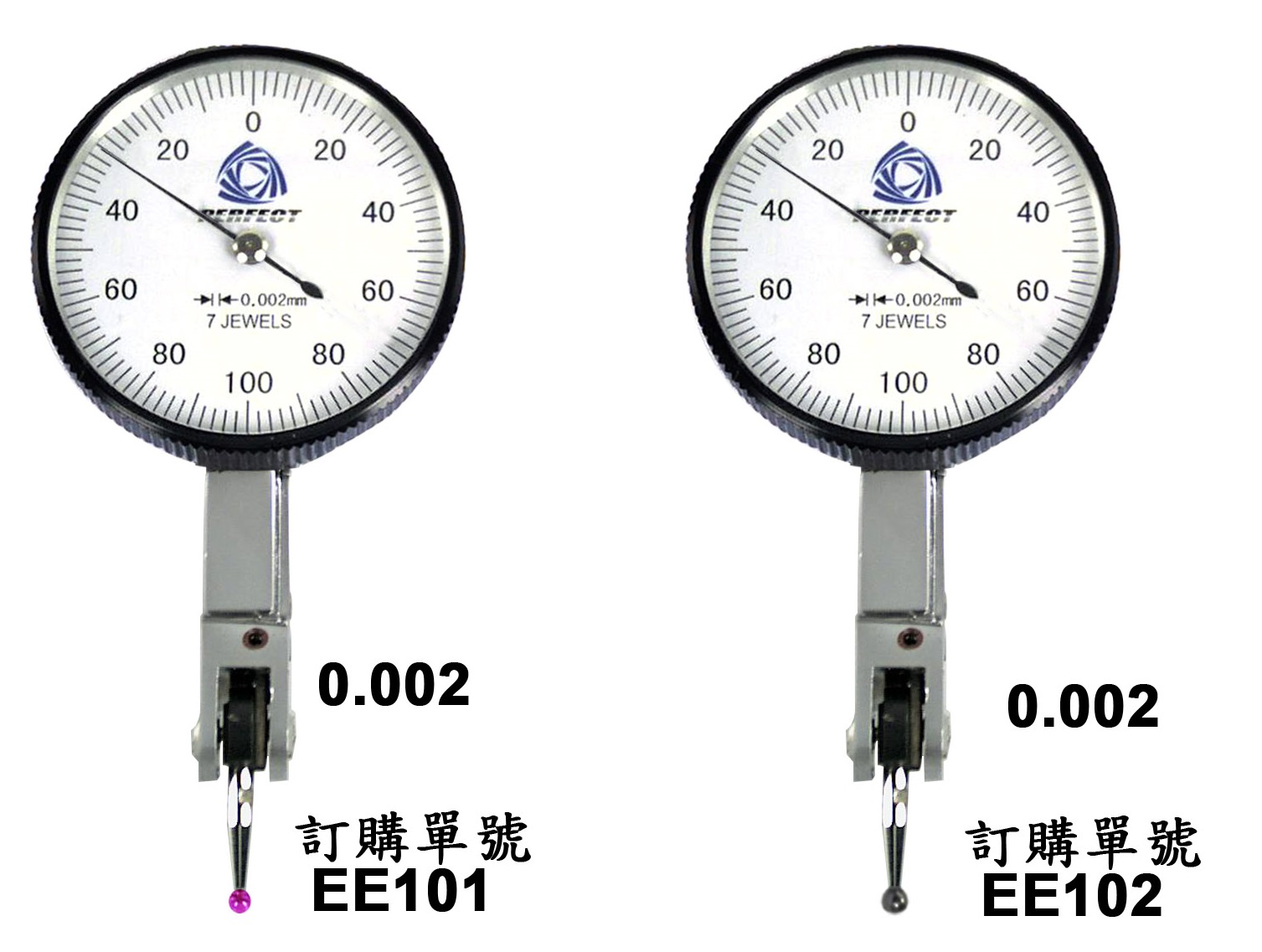

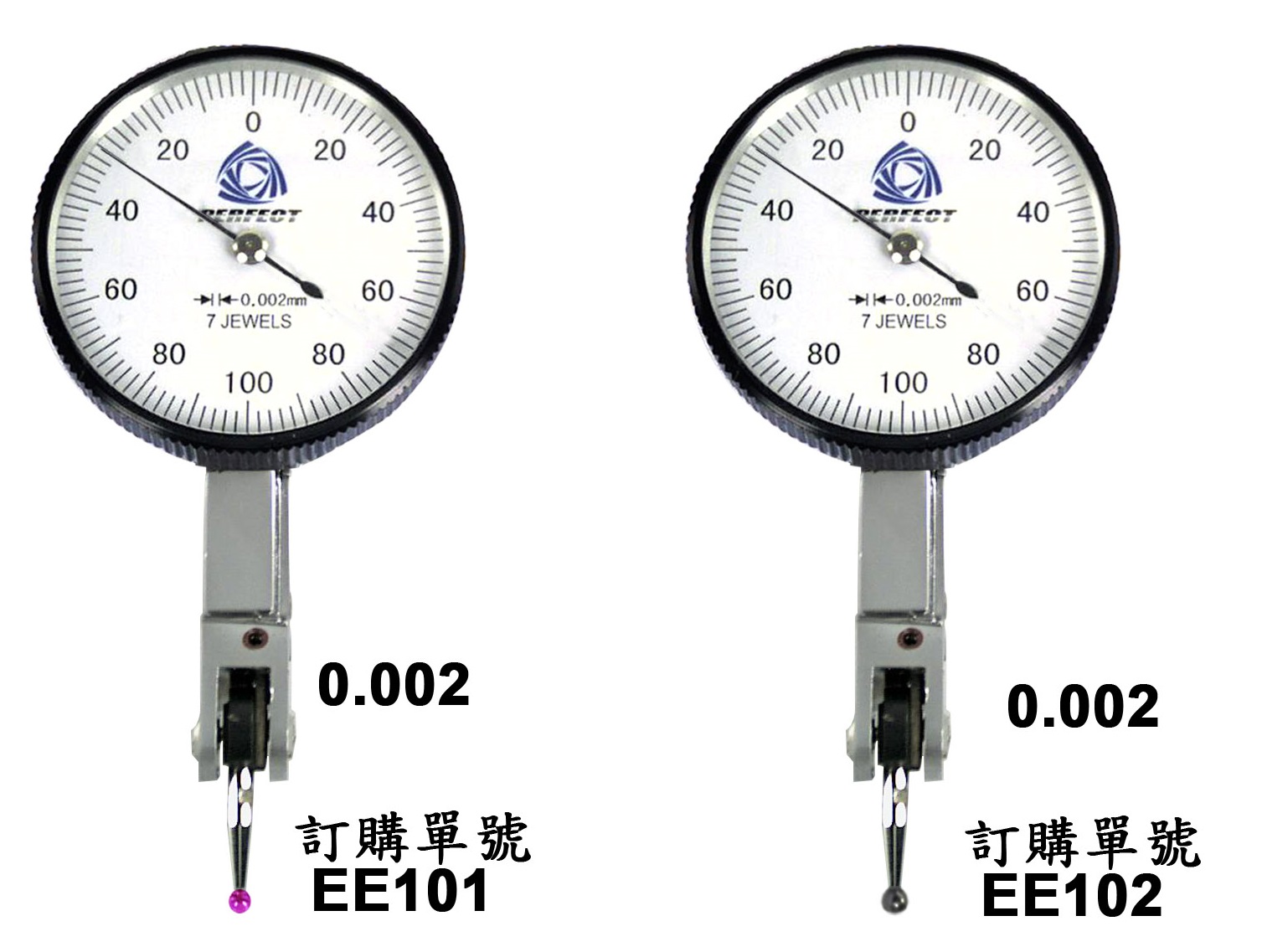

Item No. | Accuracy | Of the probe |

EE101 | 0.002mm | Ruby |

EE102 | 0.002mm | Steel |

EE103 | 0.002mm | Ruby |

EE104 | 0.002mm | Steel |

Ruby probe