325YG MCD Monocrystalline Diamond High-Gloss Insert

Characteristic

Model : 325YG

The MCD Monocrystalline Diamond High-Gloss Insert is crafted from imported MCD material, offering exceptional hardness, outstanding wear resistance, and superior mirror-finish machining capability. It is specially designed for high-precision processing of metallic and non-metallic materials requiring extremely fine surface finishes. The insert is regrindable multiple times, effectively reducing overall machining costs.MCD Monocrystalline Diamond High-Gloss Insert

High Wear Resistance and Strength

Made with high-purity imported monocrystalline diamond, featuring extreme hardness and excellent wear resistance. It remains sharp even under high-intensity, long-duration cutting conditions, significantly extending tool life.

Sharp Cutting Edge with Mirror Finish, No Polishing Needed

The edge is finely ground and polished to achieve a mirror-like finish directly, eliminating the need for secondary polishing processes.

Supports multiple regrinding cycles and is available for customized specifications.

Flawless Mirror Surface, Sharp and Durable

The tool surface is free of visible machining marks, ensuring smooth and glossy workpiece surfaces, improving product quality and processing efficiency.

Wide Range of Applications

Easily handles soft metals (such as aluminum, silver, gold, copper) and non-metallic materials (such as acrylic and plastics) with high precision.

Particularly suitable for applications requiring high gloss finishes on gold, silver, copper, aluminum, and acrylic materials.

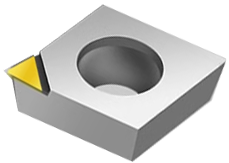

| 325YG Model | Image | Price |

APKT160402-MCD APKT160404-MCD APKT160408-MCD |  | 6800 |

CCGT120402-MCD CCGT120404-MCD CCGT120408-MCD CCGT160402-MCD CCGT160404-MCD CCGT160408-MCD CCGT060202-MCD CCGT060204-MCD CCGT060208-MCD CCGT09T302-MCD CCGT09T304-MCD CCGT09T308-MCD |

| 6800 |

DCGT11T302-MCD DCGT11T304-MCD DCGT11T308-MCD |  | |

SEHT120402-MCD SEHT120404-MCD SEHT120408-MCD |  | 6800 |

WNMG080402-MCD WNMG080404-MCD WNMG080408-MCD |  | 6800 |

TNMG160402-MCD TNMG160404-MCD TNMG160408-MCD |  | 6800 |

VCGT110302-MCD VCGT110304-MCD VCGT110308-MCD VCGT160402-MCD VCGT160404-MCD VCGT160408-MCD VCGT11T302-MCD VCGT11T304-MCD VCGT11T308-MCD |  | 6800 |

Instructions for Use:

01 Handle with Care:

Do not touch the cutting edge with fingers or any objects. Even slight contact or dust friction can damage the edge, affecting tool performance or causing failure.02 Wear Management:

If wear occurs during use, inspect the tool under a microscope to determine if it is within the regrinding range. If so, the tool can be reground multiple times to extend its lifespan; otherwise, it should be replaced promptly.