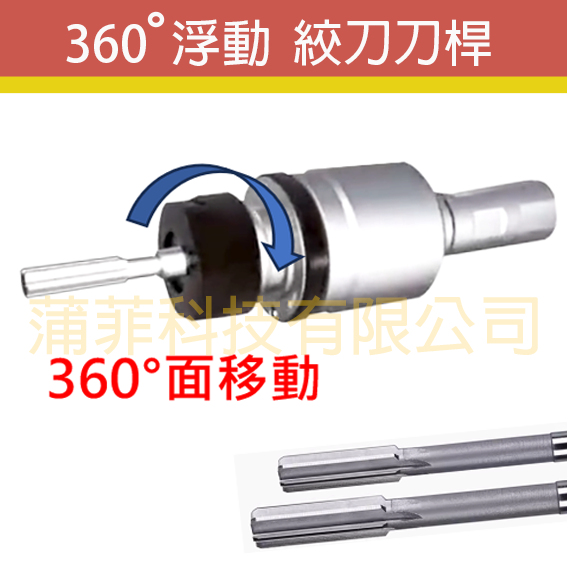

Z2R2 Floating Reamer Holder

Characteristic

Model : Z2R2

Adjustable Floating Resistance: You can finely adjust the floating resistance without limitations, ranging from automatic centering to free floating. This means you can customize the tool's settings as needed to ensure optimal performance.Tool Weight Adjustment: By adjusting the floating resistance, you can achieve better tool settings, which is beneficial for both vertical and horizontal applications. Even in horizontally-oriented adjustable automatic centering, you can keep the tool centered within the Floating Reamer Holder, preventing chatter and extending the tool's lifespan.

Combination of Ball Bearings and Sliding Bearings: This type of boring bar holder combines ball bearings and sliding bearings to facilitate smooth floating. Ball bearings are suitable for low-load applications, providing smooth motion. Sliding bearings, on the other hand, resist high-stress pressures in high-load applications, ensuring stability.

Double Sealed Protection Against Contamination: This boring bar holder is equipped with double seals to effectively prevent coolant and machining chips from entering the Floating Reamer Holder, ensuring its smooth operation.

Excellent Drilling Quality: This boring bar holder restricts tool movement to parallel floating, contributing to high-quality drilling results.

Floating Reamer Holder

When using a floating Reamer Holder on a lathe, it's often necessary to compensate for the axial deviation between

the chuck and the hole to be machined. This type of error can be eliminated by using a self-centering floating reamer

holder.

The working principle of afloating reamer holder is based on a mechanism that allows parallel axial movement.

It compensates for eccentricity between the floating reamer holder and the workpiece.

Features of the floating reamer holder include:

Ball Bearings and Axial Drive Structure: floating reamer holder typically feature unique ball bearings and axial drive

structures. These components enable smooth vertical and horizontal movements, even under high torque during the

boring process. This means they can operate effectively in high-load applications while maintaining stability.

Radial Floating: floating reamer holder have the capability for radial floating. This means they can automatically

return to the center position and achieve 360° full floating in the radial plane (with a maximum floating amount of

up to 0.8mm on one side). This helps ensure the quality and precision of the machined hole while effectively reducing

cumulative errors and secondary clamping errors.

Elimination of Spindle Runout: Using a floating reamer holder can eliminate radial runout of the lathe spindle.

The reamer holder's center remains consistent with the center of the machined hole, resulting in smoother machining

processes and improved boring accuracy. Additionally, it contributes to extending the tool's lifespan.

Increased Production Efficiency: The use of floating reamer holders can save time on calibration, tool changes,

and other auxiliary tasks, ultimately boosting production efficiency. This, in turn, helps reduce production costs and

enhances overall process efficiency.

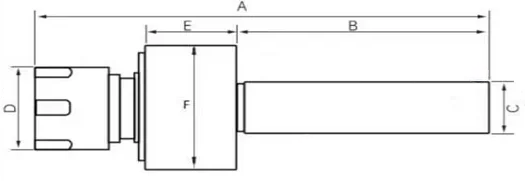

Specification Parameters Table for floating reamer holder | ||||||||

Model | Clamping Range | A | B | C | D | E | F | Floating Amount |

C10-ER11M | 1-8mm | 77 | 42 | 10 | 16 | 15 | 25 | 0-0.5 |

C16-ER11M | 1-8mm | 77 | 42 | 16 | 16 | 15 | 25 | 0-0.5 |

C20-ER11M | 1-8mm | 77 | 42 | 20 | 16 | 15 | 25 | 0-0.5 |

C22-ER11M | 1-8mm | 77 | 42 | 22 | 16 | 15 | 25 | 0-0.5 |

C25-ER11M | 1-8mm | 77 | 42 | 25 | 16 | 15 | 25 | 0-0.5 |

C12-ER16M | 1-12.5mm | 90 | 42 | 12 | 28 | 20.3 | 34 | 0-0.8 |

C16-ER16M | 1-12.5mm | 90 | 42 | 16 | 29 | 20.3 | 34 | 0-0.8 |

C20-ER16M | 1-12.5mm | 90 | 42 | 20 | 28 | 20.3 | 34 | 0-0.8 |

C22-ER16M | 1-12.5mm | 90 | 42 | 22 | 28 | 20.3 | 34 | 0-0.8 |

C25-ER16M | 1-12.5mm | 90 | 42 | 25 | 28 | 20.3 | 34 | 0-0.8 |

C16-ER25UM | 1-20.2mm | 113.5 | 48 | 16 | 42 | 32 | 52 | 0-1 |

C20-ER25UM | 1-20.2mm | 113.5 | 48 | 20 | 42 | 32 | 52 | 0-1 |

C25-ER25UM | 1-20.2mm | 113.5 | 48 | 25 | 42 | 32 | 52 | 0-1 |

Floating Reamer Holder Speed and Cutting Speed Reference Table | |||||||

Model | (Carbon Steel≦0.20%) | 0.25-0.4% Carbon steel, 41xx Steel, FCD | 45%≦Carbon Steel, SKDI, CU | SUS | SC | FC, C2XXX-CAC2XX, ADC | |

ф1-ф2 | min/rpm | 800-1000 | 600-800 | 400-600 | 500-700 | 400-600 | 1000-1200 |

F | 0.05-0.07 | 0.04-0.06 | 0.04-0.05 | 0.04-0.06 | 0.04-0.05 | 0.06-0.08 | |

ф3-ф4 | min/rpm | 600-800 | 400-600 | 300-400 | 500-600 | 400-500 | 800-1000 |

F | 0.06-0.07 | 0.05-0.06 | 0.04-0.05 | 0.04-0.05 | 0.04-0.05 | 0.07-0.08 | |

ф5-ф6 | min/rpm | 500-700 | 400-500 | 200-300 | 400-500 | 300-400 | 700-900 |

F | 0.07-0.08 | 0.06-0.07 | 0.05-0.06 | 0.05-0.05 | 0.05-0.06 | 0.07-0.08 | |

ф7-ф8 | min/rpm | 500-600 | 350-400 | 200-300 | 350-400 | 300-400 | 700-800 |

F | 0.07-0.09 | 0.06-0.07 | 0.05-0.06 | 0.05-0.06 | 0.05-0.07 | 0.07-0.09 | |

ф9-ф10 | min/rpm | 400-500 | 300-350 | 150-200 | 200-300 | 200-300 | 600-700 |

F | 0.08-0.1 | 0.07-0.08 | 0.06-0.08 | 0.06-0.08 | 0.08-0.1 | 0.01-0.12 | |

ф11-ф12 | min/rpm | 300-400 | 200-300 | 100-150 | 100-200 | 150-250 | 500-600 |

F | 0.1-0.12 | 0.08-0.1 | 0.07-0.1 | 0.08-0.1 | 0.1-0.12 | 0.12-0.15 | |

ф13-ф14 | min/rpm | 200-300 | 150-250 | 100-150 | 100-150 | 150-200 | 400-500 |

F | 0.12-0.15 | 0.1-0.12 | 0.1-0.12 | 0.1-0.12 | 0.12-0.15 | 0.15-0.18 | |

ф15-ф16 | min/rpm | 150-250 | 150-200 | 100-150 | 100-150 | 100-150 | 300-400 |

F | 0.12-0.18 | 0.1-0.15 | 0.1-0.12 | 0.1-0.15 | 0.15-0.18 | 0.15-0.2 | |

ф17-ф18 | min/rpm | 150-200 | 100-150 | 100 | 100 | 100 | 200-300 |

F | 0.15-0.2 | 0.15-0.2 | 0.12-0.15 | 0.12-0.15 | 0.16-0.2 | 0.18-0.22 | |

ф19-ф20 | min/rpm | 100-150 | 100 | 100 | 100 | 100 | 100-200 |

F | 0.18-0.25 | 0.18-0.25 | 0.15-0.2 | 0.15-0.2 | 0.2-0.25 | 0.2-0.3 | |