VVXNSUS Blade star screw

Characteristic

Model : VVXNSUS

Blade star screwTurning, milling Tooling Insert Fastener

Blade star screw

Turning, milling Tooling Insert Fastener

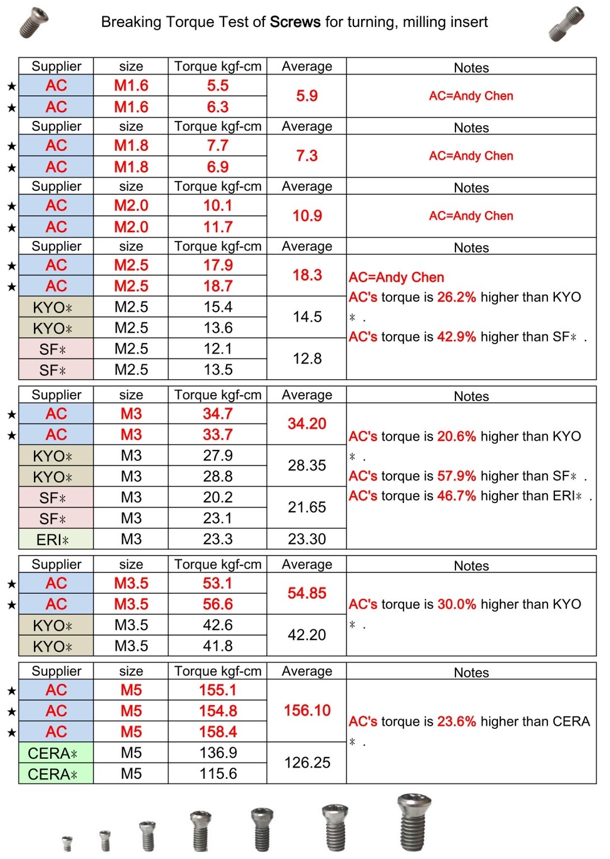

Superior stainless steel fastener, the strongest ever been made at least three times more lasting than any other existing Turning screw. According to 6 different European and Japanese companies who are specialized for turning/cutting blade solutions, they are the best screws ever been made. Internal revolution is going on those companies to replace all existing designs to the new material. 4 of those companies already stopped using traditional fastener screws and requiring full line of screws made of new material. The best performance screw ever existed which is absolutely too much important for fastening solution especially in challenging environment.

The common known disadvantages of traditional fastening screw:

A. Cannot be tight in enough to maintain insert.

B. TORX (or HEX Drive) cause to easy deforming or defect cannot tight in or be removed then complete holder need to be replaced.

C. Normal screws cause to head break easily.

D. Screw and holder get rusty easily which cause to jamming, cannot be removed or tight in.

E. Each operation of screw needs lubrication to preventing jamming.

F. Screw self life too short, spare parts frequently needed.

Advantages of new material:

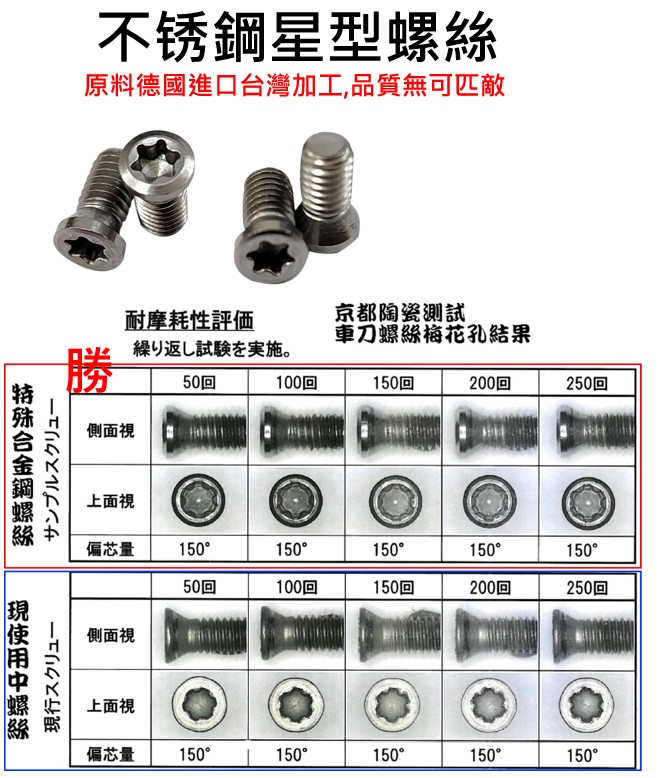

A. New material is high corrosion resistant, can resist chemical corrosion cause from cutting oil & lubrications. Screw can be tight strong and safe without jamming. Salt spray test more than 6000 hours, withstands Kesternich test at least 71 cycles, corrosion resistance 30 times better than traditional fasteners.

B. High hardness, screw drive (TORX) will not deform or defect easily.

C. High hardness, head brake chances minimized.

D. Threads will not rust from cutting oil/lubrication cause jamming.

E. The high corrosion resistance of new material can prevent thread jamming caused from rust, can safe maintenance time for lubrication while changing cutting blades.

F. Can driven completely tight, preventing vibrations while operating which cause to cutting plate damages. Full tightness can also increase accuracy of working part, and increase self life of cutting/milling plate.

G. Screw endurance of new material is three times higher than traditional screws.

H. Operative temperature is higher than SCM435 approx 135~150 ℃.

Salt Spray Test | Kesternich | Hardness HRC° | Tensile N/mm2 | |

PERFECT-CNC | Min.6000hours | Min. 100 CYCLES | 54-56 | 1500-1586 |

SCM #435 | Max.50hours | Max. 2 CYCLES | 36-41 | 1254-1331 |

SUS #420J2 | Max.150hours | Max. 3 CYCLES | 49-53 | 1390-1470 |

Attached we have included some sample screw for your study and testing.

On request we can manufacture your screw according to your drawing specification.

We are ready to provide you further infomation by request, please feel free to contact us anytime.